Doctor blades are used in a variety of printing processes to remove ink from the non-engraved portions of anilox rolls and the land areas of cell walls. The name has its origins in the use of flatbed letterpress equipment for the blades used to wipe ductor rolls.

What Is a Doctor Blade?

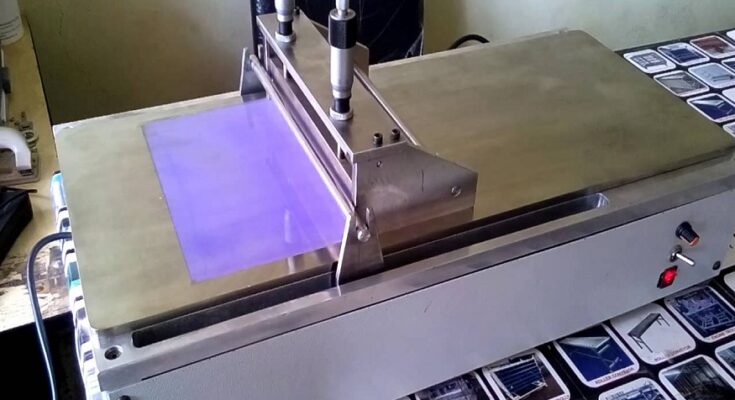

Doctor blades are inexpensive, disposable consumables used during the printing process. They are usually constructed from steel or polymer. The assembly is designed to allow for fine adjustment needed to compensate for misalignments between the blade and the cylinder axis. They may be used in conjunction with other products, such as end seals.

What Are the Types of Doctor Blades?

Most doctor blades come in either straight, lamella or bevel configurations. The straight blade is used for lower-quality print and has a straight, blunt edge. The lamella tip blade is thin at the tip and becomes larger in a step pattern or other design. Beveled blades are cut at an angle to create a beveled edge. The lamella and bevel varieties are used in printing applications that require a higher degree of precision.

Why Are Oscillating Blades Used?

All but the smallest printing machines employ oscillating blades. The oscillation helps keep the wear pattern even, which prevents particles from accumulating at the angle between the cylinder and the blade.

Are Doctor Blades Difficult To Replace?

Doctor blades are designed to be fast and easy to replace. The blade holder can be replaced on many machines by removing it from the machine, disposing of the old blade and inserting a new one and then reattaching the blade holder to the machine. Blade puller tools are available to ensure safety.

Doctor blades are an essential component of many printing applications. These disposable components help prevent wear and tear on the more expensive parts of printing equipment.